The connected software program operates according to the specs inside the SRS. The outputs and actions with the computer software are in step with the SRS.

Be ready to transform system in the course of the Unwanted fat if issues arise. Be prepared to come in early or keep late to obtain the work done and assume your producer associates to perform precisely the same.

Now chances are you'll request, what If I don’t have an HMI set up with my panel? How can I begin to see the change in the output? Nicely, that is certainly also super easy.

FAT tests are helpful not only with the close users but also for the company. Both equally events can rest absolutely sure which the equipment will fulfill all requirements on the contract, and any troubles can be fixed ahead of arriving at The client's web page.

Greater part of the effective corporations tend not to allow for delivery with the products with out prior testing or maybe the tests executed by automatic programs. Finishing up these tests is a huge turning point in each producing job.

The complete Extra fat activity is documented. It is made of a number of a checklist in a documented sort. Each checklist is executed and confirmed against its respective acceptance standards. In case the test fulfils the acceptance criteria, the test is taken into account a move. Otherwise, It is just a failure.

The manufacturer delivers Excess fat test procedure to The shopper for acceptance. The inspector shall assessment the procedures and make sure the Body fat test is done according to the permitted version of your test procedure.

Should the machines’s specification will not be based on the producer’s requirements, the Fats is alleged to get unsuccessful. check here The gear’s producer is responsible for eradicating the deviation.

The cookie is set from the GDPR Cookie Consent plugin and is also accustomed to keep whether user has consented to the use of cookies. It does not store any personal data.

Testing machines for full-ability generation is reserved for SAT. It is best if all utilities are set up and ready for use. By positioning a load to the devices, it might be tuned and adjusted to respond to all on-site conditions, as desired.

Each test case of the Excess fat must be documented while in the doc and if the tests' standards and objectives are fulfilled. The failures that were uncovered for the duration of tests are recorded and the reasons for failures are documented, accompanied by techniques to rectify the issues.

Therefore, effectively adhering to a arranged method is important to get the desired results and avoiding potentiality ask. What is a factory acceptance test? Learn how DXP approaches the our acceptance Test protocol, And exactly how OIL is sweet for shopper serving!

Fats Checklists might help recognize probable challenges right before output or delivery and assist to stop pricey merchandise rework, creation delays, and purchaser dissatisfaction.

Soon after A prosperous SAT, a last report is ready. get more info It mentions detailed SAT Functioning, success, and personnel included. The equipment producer also carries out teaching with the tools customer staff, along with a education report is also ready.

Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Anthony Michael Hall Then & Now!

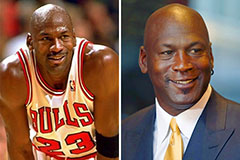

Anthony Michael Hall Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!